Description

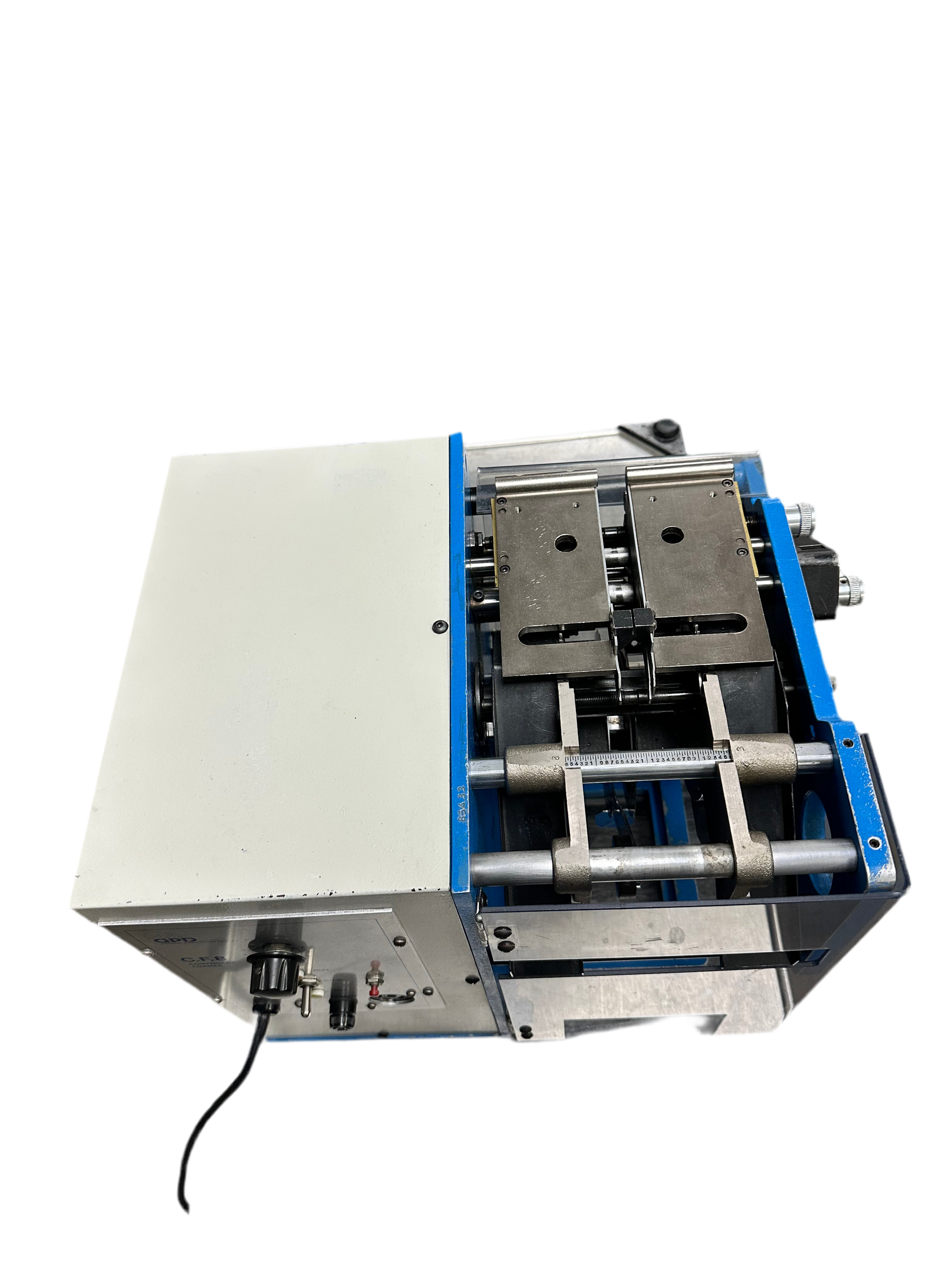

GPD CF-8 Axial Component Lead Forming Machine

All CF-8 Lead formers go through an extensive reconditioning process, and are fully calibrated with the OEM kit. Each machine includes :

- 1 Set of transport wheels (Small .015-.030", Medium .030"-.045", or Large .045"-.060")

- 1 set of Horizontal bending die (90 degree form) - size will be based off transport wheel

- 1 Pin die for hairpin forming

- New style infeeder allowing for both taped and single part loose feeding

- Foot Switch

Description

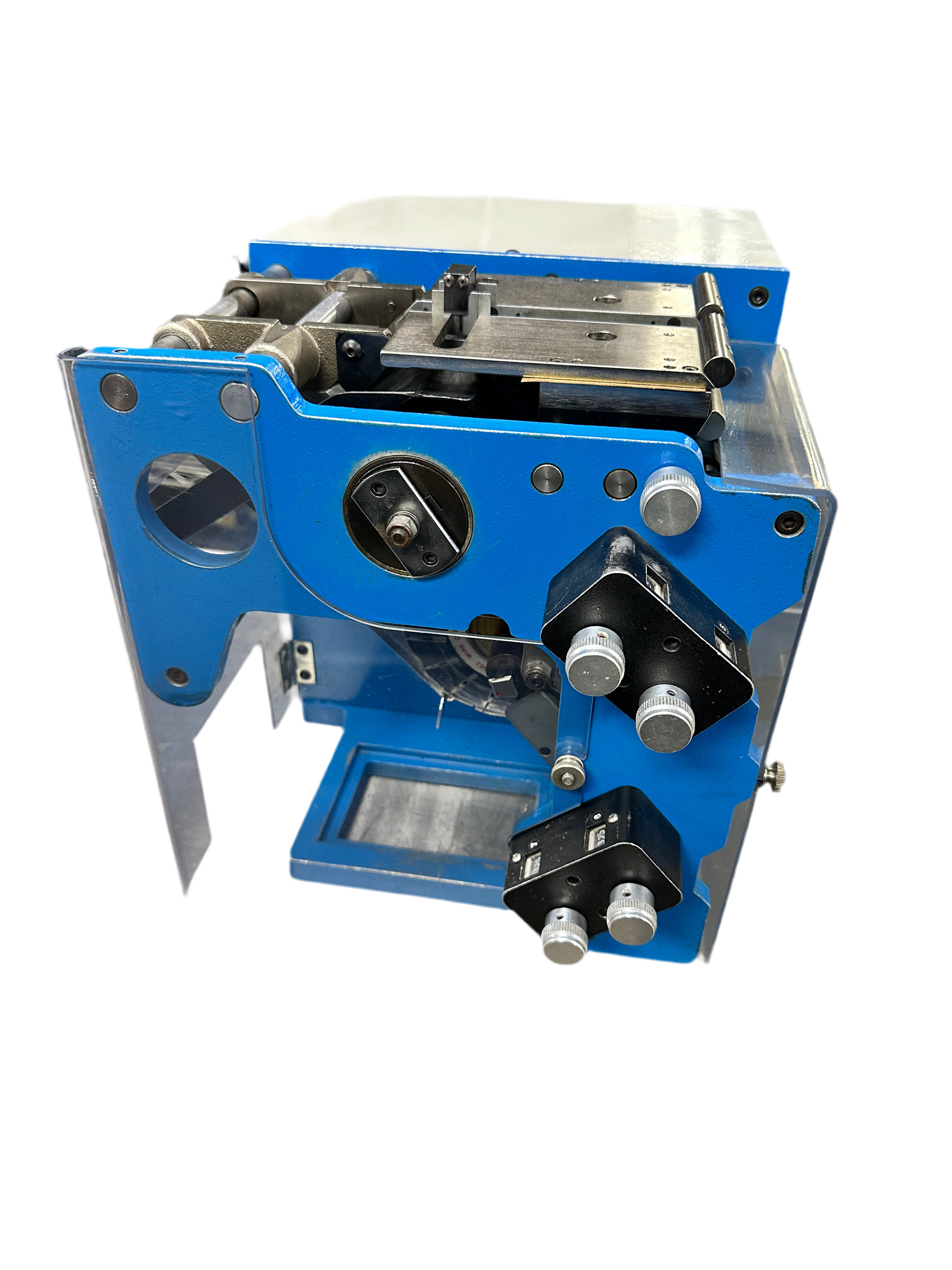

- Eliminates component body-to-lead stress

- Forms axial leaded components either vertically or horizontally

- Repeatability of station settings are controlled to ± .002″ (0.05 mm)

- Form loose or taped axial-leaded components

- Tooling change-over is quick and easy

- Form components with lead diameters between 0.015″ (0.38 mm) and 0.060″ (1.52 mm)

Key Features (additional forms require die sets - available for additional cost)

- Control lead protrusion below the pc board with cut-off lock-in tooling to eliminate post solder trimming.

- Lock-in tooling prevents component “float” during wave solder process.

- Stand-off or flush mount lock-in forms for components with lead diameter from .015″ to .060 (0.38 mm to 1.52 mm) and lead material from copper to steel.

- Feed loose or taped components with the same machine. Feed from reels with standard Tape Feeder or in bulk with optional Jacobs Ladder.

- Reduce setup time through repeatable station settings and GPD’s exclusive Calculator Software Package.

- The CF-8 meets the most difficult standards for stress-free/nick-free forming during the forming sequence.

- Standard tooling in stock.

- Station adjustments available in inches or metric.